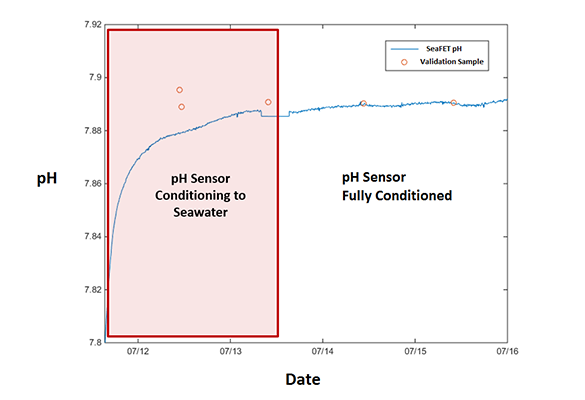

These data originated from the SeaFET’s External Reference. Before the ISFET pH sensors can accurately measure pH, this Ag/AgCl reference electrode must assimilate to local Bromine and Chloride ionic concentrations. This process typically takes 24-48 hours upon entering a new environment. Once conditioned, the pH data remains stable until the SeaFET exits the water.

The data in question shows this conditioning period in the highlighted section. The SeaFET’s pH response begins around 0.1 pH off from the validation sample and steadily climbs towards the correct value as the reference adjusts to new water. This initial offset is normal for a SeaFET– incorrect data at the beginning of the deployment is not indicative of poor calibration or sensor failure.

Storing water from the deployment site in the SeaFET’s wet cap can help reduce this conditioning period. When the seawater in the wet cap is different from the seawater at the deployment site, the external reference electrode must recondition to the new chemistry. Storing the sensors in water from the deployment site allows the SeaFET to pre-condition itself during storage, providing high quality pH data that much faster.