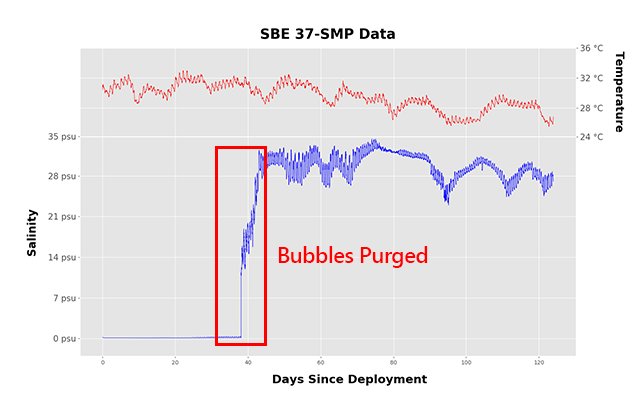

This SBE 37-SMP MicroCAT had bubbles caught in the conductivity cell in the first 38 days of the deployment, likely from a clogged flow path. Air that is unable to escape from the plumbing can prevent the CTD’s pump from running properly, and may potentially encase the electrodes within the conductivity cell in a bubble. If these electrodes aren’t conducting to one another, the CTD will output a near-zero salinity measurement. That was likely the case here: clogs in the plumbing prevented air from escaping, keeping the pump from flushing air out of the conductivity cell.

All pumped SBE 37s (37-SMP, SMP-ODO, SIP, IMP-IMP-ODO) have a U-shaped flow path with an air-bleed valve at the bottom of the U meant to purge bubbles. If sediment or fouling is clogging this opening at the beginning of the deployment, bubbles may become trapped in the 37’s flow path. Cleaning the air-bleed valve and flushing the plumbing yielded expected salinity for the next deployment.